The Manufacturing Manifesto

London, October 2024

Coalbrookdale by Night by Philip James de Loutherbourg

Isembard introduction

Isembard is building the software-first manufacturing super prime for critical industries. Our mission is to forge industrial acceleration. This thesis charts why Isembard was founded.

1 - The world is built upon production

What is the most important event in the history of humanity? Have a guess.

Not the invention of farming. Not the founding of the first city. The biggest single impacter on our collective living standards has been the Industrial Revolution in the late 19th century. And all of us seem to have forgotten that.

Underlying everything the world takes for granted today; the data centres that enable large language models, the connective tissue of the internet, the power systems that make things work, everything relies on humanity’s productive force upon atoms.

1.1 - The impact of the British industrial revolution on life

2 - We are losing our productive edge

Let us start with a story. When Isambard Kingdom Brunel’s father saw British soldiers returning from the Peninsula War with injured feet due to shoddy footwear suppliers, he resisted the urge to turn a blind eye. He founded a shoe factory in Battersea, South London, and went on to sew up the market by improving the product, extending soldiers lives and hiring veterans onto the factory floor.

"he had witnessed at Portsmouth in 1809, the disembarkation of some remnants of that gallant band [from the Battle of Corunna]. He had learnt how greatly the want of shoes had contributed to the losses which the army had sustained, and his kindest, deepest sympathies were at once enlisted”

What are the broken boots of today that need fixing? Three things: the economics, culture and technology of manufacturing.

Europe at the turn of the 20th Century constituted 70% of global manufacturing GDP. Yet today the UK stands at just 0.3%, with Europe’s share reduced by almost 60%.

This does not have to be the case. The cost of manufacturing and financing machinery in China is rising thanks to an ageing workforce and reduced state financing for machine tools and growing Chinese wages. Automation along the manufacturing process will reduce the gains from offshoring with Europe now home to the largest pool of high end machine tool makers in the world, alongside the highest calibre machinists and a burgeoning software base.

Yet manufacturing is still a fairly clunky industry. While management consultancies wax lyrical about Industry 4.0 and ‘Digital Twins’, little transformation has actually occurred. Once you get past prototype stage, the cost of any one single design change massively increases. Flowing production lines have higher capex and are therefore hard to change. In contrast to software, where incremental capex on the production line is effectively zero.

The biggest failure mode however is culture. The zeitgeist should encourage building in not just bits, but atoms. And we need to capture and replicate that coolness so that the cycle of businesses we collectively found as a species does not just make small, largely irrelevant parts of a our lives better.

Matt Clifford at Entrepreneur First said it best when he classified how ambition has changed throughout the centuries. In the medieval period the most ambitious people went into the clergy. Through the Napoleonic era it became the military. At the turn of the 21st Century it became finance. And now it is becoming startups.

But dive, fractal like, into the cohorts of companies starting today and too many are not solving problems to do with space flight or human longevity. Too many are making HR SaaS a few basis points more efficient. An opportunity has therefore arisen to attract the best and the brightest to quests of worthy ambition.

2.1 - Financial Times analysis of industrial robotic installs

2.2 - The Economist analysis showing robotic impacts

2.3 - Valves are a hard problem to crack for humanity

3 - A multi-polar world is rising

Humanity’s productive force can be turned towards good, as well as evil.

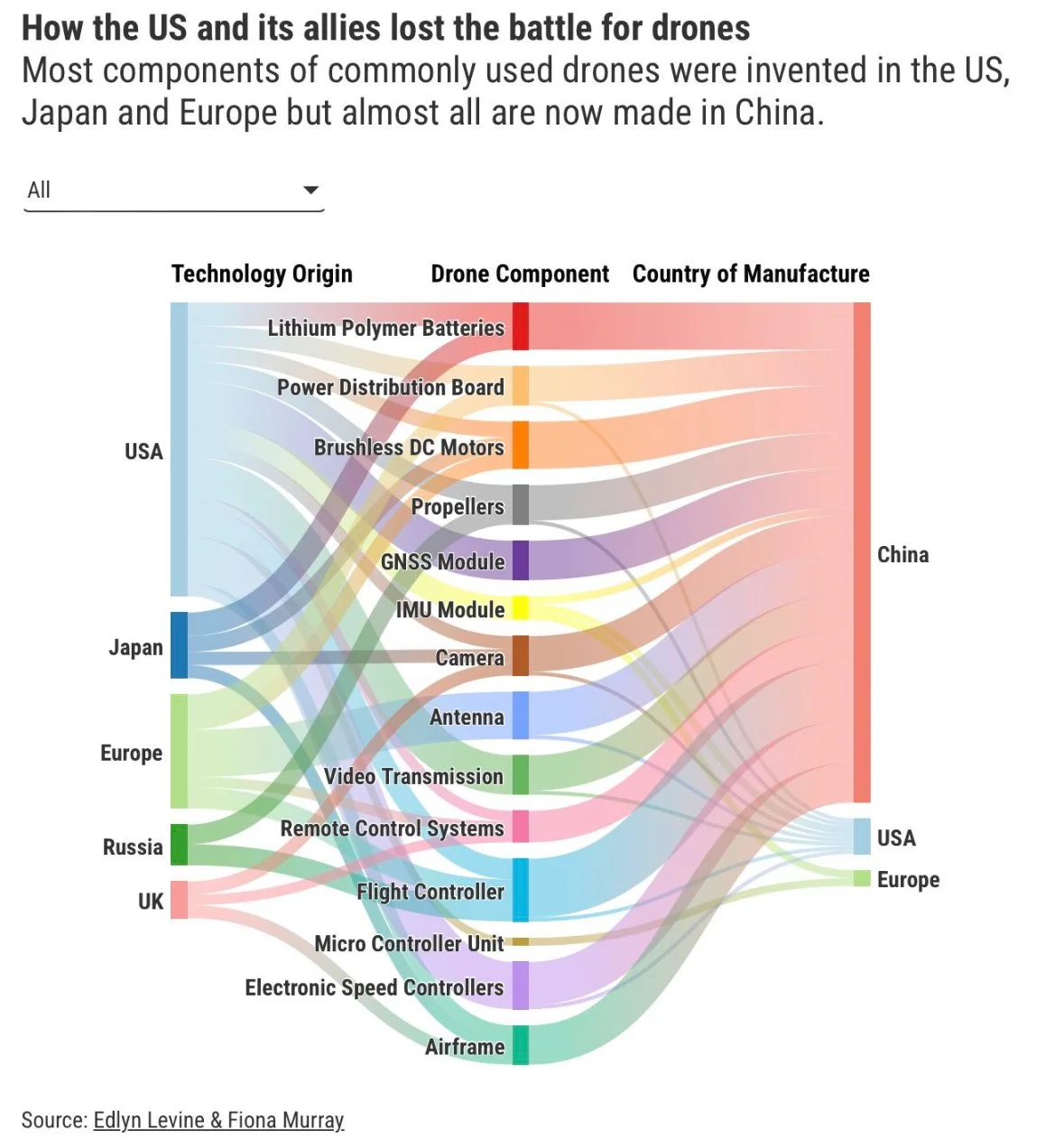

Russia, China, Iran and North Korea have been marshalling. And drones make an interesting case study as one of the newest vectors in our millennia long struggle between humans in conflict.

There are many things to take away from the rise of un-crewed systems. The prevalence of modern consumer grade electronics and parts. The smaller size profile. The ability to be controlled remotely and via artificial intelligence. The importance of mass and quantity. The variety of different platforms. The rate of iteration. The production cost differential. But the key things to take away is this.

Your supply chain is your weapon.

Yet drones are only one part of the multi-polar puzzle that we must solve. The People’s Liberation Army of China can currently out produce the United States in ship production, in large part due to its thriving steel capacity. And its not just drones and ships. Semi-conductors for chips. Rare minerals for nuclear. Machine tools for missiles.

The list of current and future economic weapons are broad. Yet we can look to the past, for lessons about our future.

In the dark years of the late 1930s when Britain stood alone against Nazi tyranny, scaling aircraft production helped defeat the Luftwaffe. While Goring imagined the Royal Air Force a weak and broken adversary, the Ministry for Aircraft Production headed up by the peripatetic Lord Beaverbrook manufactured the angels that would save Britain.

The learning? You need a clear goal. You need to work like hell. And you need to coalesce the forces of production in a single direction.

3.1 - An excerpt from The Splendid and The Vile

3.2 - Global steel flows from raw material to end use

3.3 - The drone component supply chain

4 - Isembard’s bet on the future

So we want to spark a new industrial revolution. What is the game plan? Well the investor Keith Rabois gives us a good pointer.

Find large highly fragmented industry w low NPS; vertically integrate a solution to simplify value product.

That industry is the production of precision parts for critical industries. It’s a large market, tick. $132 billion of revenue every year across Europe and the United States growing at a compound annual growth rate of 10% over the next decade. It’s a fragmented low NPS market, tick. 95% of CNC machines are owned and operated by small businesses. It’s prime for vertical integration, tick. Small businesses themselves have little access to the core fundamentals that will make their business sing. And by focusing on building modular, software-first manufacturing units Isembard can build the ability to have strategic depth. This is important.

During World War II, Russia underwent a massive industrial transformation, rapidly converting its economy to focus on manufacturing for the war effort. By 1942, the Soviet Union had moved over 1,500 factories eastward, away from the advancing German front, and increased production of tanks, planes, and artillery. The T-34 tank, produced at a rate of 1,000 units per month by 1943, became a symbol of Russia's industrial might. Despite severe resource shortages, the Soviet Union’s total war production grew by nearly 50% between 1941 and 1944, significantly contributing to their victory.

Fast forward to today, and the Royal Navy faces supply chain problems that, while different in nature, echo the wartime struggles of rapid production scaling. With its reliance on a fragmented network of small suppliers for precision parts, the Royal Navy is vulnerable to delays and disruptions. Like WWII Russia, modern defence industries require agile manufacturing systems and capacity to scale quickly, but the current structure lacks the depth needed to maintain consistency and speed under pressure.

The key bets for Isembard are to modernise machine shops, focus on software and robotics aided manufacturing for better efficiency, build strategic depth to ensure production scalability, and help solve the prototype, production and repair bottlenecks for critical industries.

4.1 - The movement of Russian factories during WW2

4.2 - European missile and ammunition production sites

4.3 - British Royal Navy ship states

5 - A Software-First Manufacturing Super Prime

Our long-term vision is to create a powerful manufacturing company that leads in multiple industries. We will build a network of flexible, specialised factories that can quickly adapt to different sectors such as defense, energy, and aerospace. Our focus is on using software, intelligence and robotics to make production faster and more efficient. By integrating everything from factory design to product delivery, we aim to build a business that can meet the needs of the future.

We hope to see you in the factory sometime soon.

5 - Production posters from WW2